29.12.2019

Value of innovations

In the current economic world, it has become de rigueur to talk about import substitution with respect to the novel technologies and the development of domestic industry. However, what are the objective criteria by which a product may be treated as truly innovative? Which companies can afford the ownership and implementation of this unique technology? And how much should cost the final product of good production? Let us examine this question using as an example our own fire vehicle production chain, from aluminum sheet to the finished vehicle.

First, let us define what is a fire truck. It is chassis and superstructure, which comprises a pump – the "heart" of the vehicle, tanks for fire extinguishing agents, and a variety of accessories. In our country, we usually use KamAZ and Ural chassis, sometimes – foreign chassis Iveco, Suzuki, MAN. Less common are MAZ, Mercedes, ZIL chassis.

List of domestic chassis is limited. The manufacturers generally use the same models depending on the capacity of a water tank. Our company has its own exclusive chassis KAMAZ 5387 4x4. Its extended cross-country and load capacity combined with a low center of gravity make it possible to take on board more equipment, while maintaining agility and compliance with weight regulations.

You will get the best idea about how a fire truck is assembled directly in the production shop. The first and the main distinguishing feature of the innovative production is the use of technology and process operations inaccessible during ordinary assembly procedure.

Thus, the assembly begins with bending and grinding of parts cut with a jeweler's precision by laser cutting. It is worth noting that not all and even the largest European manufacturers can afford using laser technology in such a massive scale.

Aluminum is a lightweight corrosion-proof material. A frameless superstructure is assembled using aluminum according to the Russian unique adhesive technology. Structural part are glued to each other, while reference points are secured with bolts. Adhesive bonding is more flexible, and the joints like the superstructure itself, do not rust, do not burst, and sustain less pressure when the vehicle is in motion.

The bottom, sidewalls and roof are reinforced with plastic sandwich panels, providing an additional strength to the structure, as well as thermal and noise insulation. Plastic "cells" are being cut directly on site during superstructure assembly. For comparison: other fire trucks are not provided with insulation at all, or cheap fragile foam may be used instead. Heating of a pump therein occurs due to exhaust gases.

Bending and polishing are very expensive high-precision operations, providing optimum connectivity and reliability of the construction. An extensive use of bending allows us to avoid welding joints, which are exposed to corrosion and divergence during operation.

The aluminum superstructure weighs much less than steel, which means that the finished fire truck can take on board more useful weight by extending its functionality. On all-wheel drive chassis it gives the opportunity to install additional options (e.g., a winch) and other equipment.

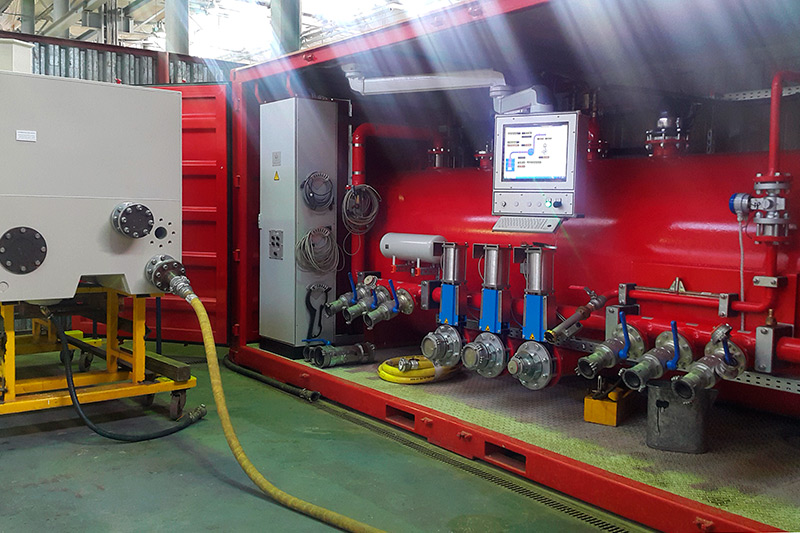

The second important criterion that distinguishes high-tech products is the use of qualitatively new modern materials. In the production of vehicles our company always tries to use something different, something that has never been used before in the automobile industry. Thus, water and foam tanks are made by special order from the Russian manufacturer of polypropylene. This is a unique lightweight and durable material that does not react with chemically aggressive environment. This tank will never rust, leak or get frozen. It is suitable for any type of foaming agent as well as drinking water without impairing its quality. The term of service of the tank - up to 25 years. Durability of 1-cm-thick polypropylene walls is checked on a special test stand equipped with a computer system (diagnosis by hydrostatic pressure). Once our Austrian partners announced that the normal working pressure of monitors line should be 12 atm at 15 atm reference pressure. By Russian standards, the working pressure should be 12 atm as well ... but our tank withstood the test pressure of 25 atm! As a result, the Russian product withstood the pressure twice the norm, which surprised the vaunted Western technologists.

Ordinary Russian producers use welding for a stainless steel tank. It quickly corrodes in the most vulnerable areas: weld seams and the bottom. By the end of the life cycle (7 years under GOST) such a tank is not suitable for transporting extinguishing agents, especially drinking water.

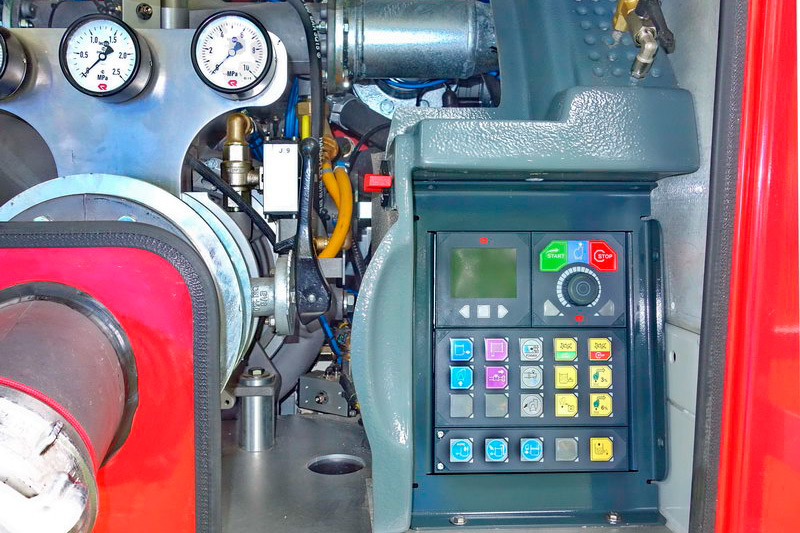

The "heart" of the firefighting tanker is a pump. The development of this industry in Russia stopped at the level of 1980s. A "choice of one" prevails in the market: tankers of the middle class type (up to 5,000 l), as a rule, are provided with the NTSPN-40/100 pump produced by Lievens firefighting engineering factory (basic mechanical PN-40 prototype of the 1970-s with slight modifications). After creation of the PA «Fire-Fighting Special Technics» in 2008, fundamentally new vehicles equipped with pumps with electronic remote control, automatic control systems and a variety of extinguishing systems entered the market.

The NH-30/35 pump with normal and high pressure sections comes complete with automatic foam-mixing and foaming agent flow control systems. Communications are made of precious metals and bronze, installed to protect the system from overheating and clogging. The pump does not require supervision, topping up oil or other operations in continuous operation, in contrast to the NTSPN, which at all times shall be attended by a crew member for the visual and thermal control. RBI pump casing is protected against mechanical damage and freezing, and for heating water and foam service provided by the engine to maintain a constant temperature of at least + 5 * even with wide open compartment.

Pump control is duplicated in the driver's cab. Information is displayed on the monitor.

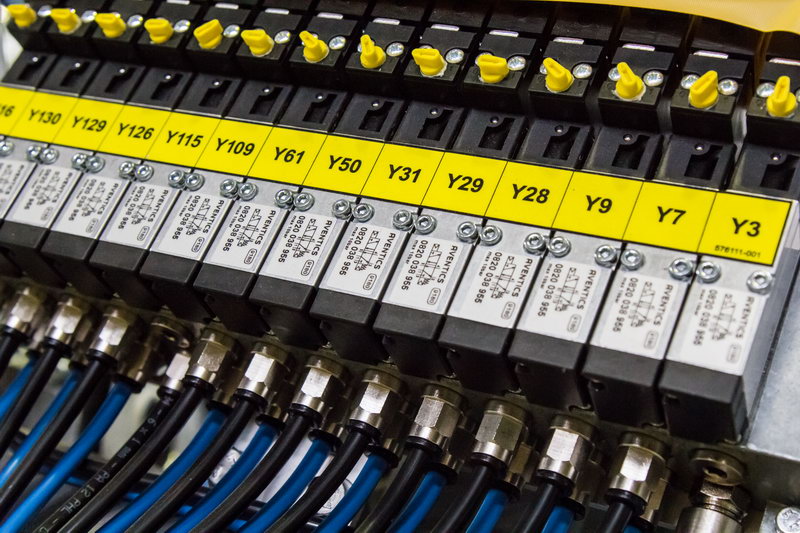

Electronic system controls all operations of the pump system and the flow of fire extinguishing agents. The controls are simple and intuitive. Under proper operating conditions, the pump will run 30 years without any repair intervention. Reliability has been proved by 150 years’ experience of Rosenbauer, the world's leading fire machinery manufacturer.

Another high-precision extinguishing system provided only in the vehicles of FFST is a fire water monitor with joystick electronically controlled from the cab. The monitor is capable of supplying a stream of water or foam at a range of 70 meters, which ensures a safe location of the vehicle from the fire source. With RBI pump and the monitor it is possible to quench fire during vehicle motion without power loss (the system is especially important for the airport crash tenders). There are no electronic analogues on the Russian market.

Fire superstructure is sewed around the perimeter of heat-resistant plastic panels. Plastic is lightweight, durable, non-corrosive, and does not require maintenance costs for updating the paint layer. Bright stylish design is also a part of the modern firefighting truck image.

A very sad example of extinguishing fire at a Moscow warehouse, where 8 firefighters were killed. Backlight car compartments, PA FFST and spotlight ladders were the only sources of light. Photo by ID "Kommersant".

Recognizable white-blue "cap", flashing lights and a gallery with LED-lamps has streamlined ergonomic shape, protecting them from mechanical damage when maneuvering. Conventional "cap"-flashers can be easily ripped when caught by a branch or wire in the arches. All optics in the vehicle are LED type (bright light with minimum power consumption and maximum durability). The compartments have automatic backlights that ensure safety and comfortable operation. Very often, this illumination is the only light source in the facility.

Safety and security issues, moreover, comfortable working conditions for those who are busy saving other people's lives, are pushed into the background in our country. Somehow, it is believed that firefighters can and must overcome any harsh conditions without complaining or wishing anything more. Unfortunately, this common misconception proves not so much the true grit of our firefighters, but more the lack of efficient and high-quality tools. It is a silent reproach to those who should provide them with good working conditions. Our firefighters deserve it in the same way as their foreign counterparts.

In a case of an emergency, human lives may depend on the most insignificant details. Our company manufactures the most modern vehicles in Russia and completes them with equipment of better quality than specified by GOST. All these systems are nothing else but high-precision instruments for the most rapid and effective aid. Let us discuss some details.

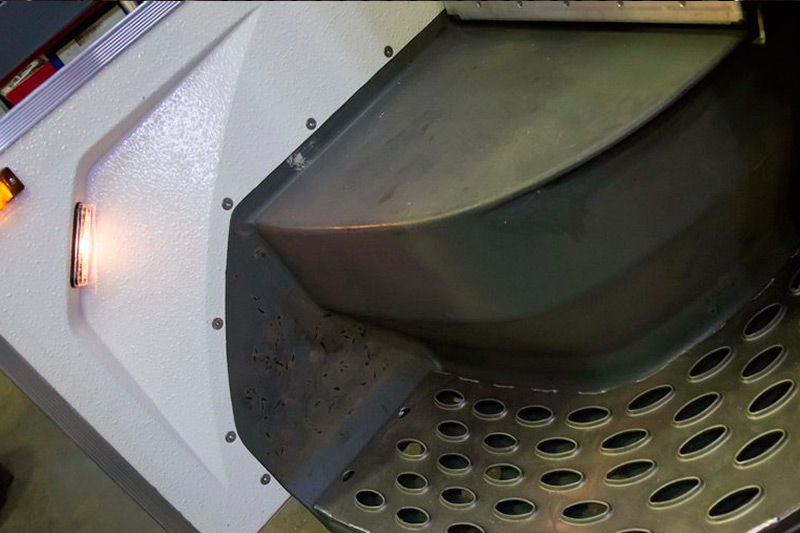

– 60-meter hose reel with electronic winding and high pressure nozzle (with 80 meter extension). This means that the machine can extinguish a fire, while the source is 20 meters away - for example, in the case of obstructed passage due to parked cars. Rubber reel does not require drying, the operator simply pressing the winding button, and it will return to its initial position. The jet of extinguishing agent supplied is regulated by finely pulverized "water mist" to provide direct stream. Fire may be extinguished by both water and foam, including compressed air foam, a very "sticky" and dense, that prevents the spread of fire to adjacent objects. In the event of a fire in an apartment building, it means that the flame may be extinguished in spots and gently, without flooding several floors below. It is possible to provide such foam to a height of 300 meters. And it is the only system in Russia for extinguishing fire at high-rise buildings with high efficiency.

– Ergonomics and easy access to the compartments save precious seconds. Bracings do not stick, do not burst, and do not freeze together, the tool can be easily taken using protective gloves. In light rotary shelves placed more equipment than even provided by GOST, so the machine can perform several functions at the same time and save the number of trips crews.

– Easy, quick and safe exit from the cabin is provided by doors with rotary stages of propulsion type. Firefighter comes out in full length and in full uniform while wearing breathing apparatus balloons. There are no analogues of such access to the crew cabin in the Russian market.

It should be noted that a modern firefighting truck with the listed systems and functions cannot be cheap. Price policy for vehicles of PA “FFST” is formed by several important factors:

- Russian unique assembly technology.

- Use of innovative high-quality materials, highly technical operations, and production methods.

- Electronic control system. Computer monitoring.

- Exclusive chassis, unique equipment and firefighting systems.

- Use of only original certified spare parts and components.

- Versatility and wide range of tasks, which 1 unit of such machinery instead of several "traditional" one is capable to deal with.

The vehicle is a high quality, multifunctional tool, on which the lives of rescuers and those being saved largely depend. The better and more convenient it is, the easier and faster the firefighter can do his job. Materials and technology, which our vehicles are made of, allow it to last three times longer than the useful time period stipulated by GOST. At the end of the life cycle (7/10 years) it is enough to upgrade the chassis, conduct preventive repair (if required) of a superstructure and continue the operation. At the same time, the 10-year-old vehicle made of stainless steel will be the extent of deterioration that it is better to write it off and buy another "cheap" copy.

Modern technological development: increasing generation capacity, high population density and movement, the growth of cities, including high upwards, require continuous improvement of rescue systems. Rejecting the innovative and truly innovative products, there is a risk to bring the industry decades backwards. And this will inevitably lead to a decrease in the quality of care and may result in a string of tragedies.

Choosing a modern multi-functional product is not only reasonable and long-term investment in the future of the fire trucks park. It is a great support of the productive sectors, reducing repair and maintenance costs, with the exception of losses due to downtime or limited functionality. The choice of innovative equipment, finally, is a respect for the hard work of firefighters and concern for the safety of both sides of salvation!